At Xptronics Inc, we take pride in delivering high-quality electronic assemblies built with precision and care. One of the key processes that defines our manufacturing excellence is Surface Mount Technology (SMT) — the foundation of modern electronics production.

What Is SMT?

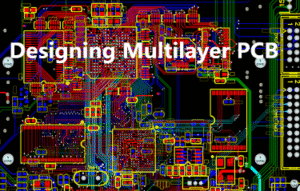

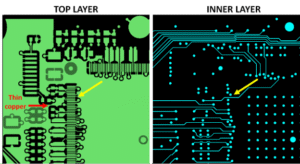

Surface Mount Technology is a method of assembling electronic components directly onto the surface of a Printed Circuit Board (PCB). Unlike traditional through-hole methods, SMT allows for smaller components, higher circuit densities, and faster assembly speeds — ideal for today’s compact, high-performance devices.

Step 1: Solder Paste Printing

The SMT process begins with the application of solder paste to the PCB using a stainless-steel stencil. This ensures that paste is accurately deposited only on the pads where components will be placed. At Xptronics Inc, we use high-precision printers to guarantee consistent coverage and perfect alignment.

Step 2: Automated Component Placement

Next, the prepared boards move to our pick-and-place machines, where components such as resistors, capacitors, and ICs are placed with extreme accuracy. These machines can place thousands of components per hour, ensuring both speed and precision. Each component is positioned exactly according to the design file, down to fractions of a millimeter.

Step 3: Reflow Soldering

Once all components are placed, the boards enter the reflow oven. This controlled heating process melts the solder paste, creating strong, reliable connections between components and PCB pads. The temperature profile is carefully tuned to avoid thermal stress and guarantee solid joints.

Step 4: Inspection and Quality Control

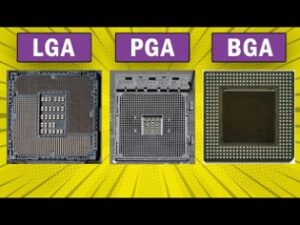

At Xptronics Inc, quality assurance is integral to every stage of production. After soldering, each board undergoes Automated Optical Inspection (AOI) to detect any potential misalignments, solder bridges, or missing components. For more complex assemblies, X-ray inspection is used to verify hidden solder joints, particularly under BGAs and QFNs.

Step 5: Testing and Final Verification

Before shipment, boards are electrically tested to ensure full functionality. Our commitment to precision and reliability ensures that every assembly meets customer specifications and industry standards.

At Xptronics Inc, we combine advanced SMT technology with expert craftsmanship to produce electronic assemblies that perform flawlessly in the field. Whether for prototyping or full-scale production, our goal remains the same — to deliver quality you can trust, every time.