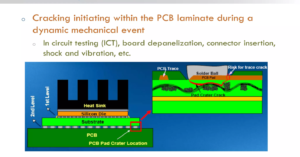

Printed Circuit Boards (PCBs) are the backbone of modern electronics, and as devices become more compact and complex, multilayer PCB layouts have become increasingly important. Unlike single or double-layer boards, multilayer PCBs stack multiple conductive layers separated by insulating material, enabling higher circuit density, improved performance, and reduced size. Designing a multilayer PCB requires careful planning, technical knowledge, and a systematic approach to ensure signal integrity, manufacturability, and reliability.

Why Choose a Multilayer PCB?

Before diving into the design process, it’s worth understanding why multilayer PCBs are chosen over simpler alternatives:

- High Circuit Density: More layers allow for complex circuitry without enlarging the board footprint.

- Improved Signal Integrity: Controlled impedance and dedicated power/ground planes reduce noise and crosstalk.

- Compact Size: Essential for modern electronics such as smartphones, wearables, and IoT devices.

- Better Power Distribution: Power planes ensure even voltage delivery across the entire board.

Steps in Designing a Multilayer PCB Layout

1. Define Board Requirements

Start with clear specifications. Consider:

- Number of signals and layers required

- Electrical performance (speed, frequency, impedance)

- Mechanical constraints (board size, shape, connectors)

- Thermal requirements and expected operating environment

2. Layer Stack-Up Planning

The stack-up defines the order of conductive and insulating layers. Common configurations include:

- 4-layer stack-up: Signal → Ground → Power → Signal

- 6-layer stack-up: Signal → Ground → Signal → Signal → Power → Signal

A well-planned stack-up improves EMI shielding, signal integrity, and reduces manufacturing challenges.

3. Component Placement

Effective placement is crucial:

- Place critical components (MCUs, FPGAs, power regulators) first.

- Group related parts logically (e.g., decoupling capacitors near IC power pins).

- Maintain clear routing channels for high-speed signals.

4. Routing Strategy

Multilayer routing requires discipline:

- Assign signal types to specific layers (e.g., high-speed signals on inner layers).

- Use ground planes as reference for controlled impedance.

- Minimize via usage on high-speed paths to reduce reflections.

- Route differential pairs with consistent spacing and length matching.

5. Power and Ground Planes

Dedicated planes are critical for stable operation:

- A solid ground plane reduces EMI and provides a reference for signals.

- Power planes minimize voltage drops and noise.

- Use multiple vias to connect components to planes for low impedance paths.

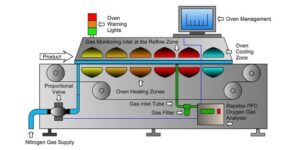

6. Thermal Management

Multilayer boards can trap heat. To manage this:

- Place thermal vias under heat-generating ICs.

- Use copper pours for heat spreading.

- Consider adding heatsinks or thermal pads if necessary.

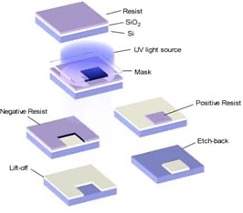

7. Design for Manufacturability (DFM)

Keep fabrication constraints in mind:

- Minimum trace width/spacing

- Drill sizes for vias

- Copper thickness

- Layer alignment tolerances

Collaborating with your PCB fabricator early ensures your design is cost-effective and manufacturable.

8. Simulation and Verification

Before finalizing the layout, run simulations:

- Signal Integrity (SI): Check for reflections, crosstalk, and impedance mismatches.

- Power Integrity (PI): Verify power distribution and decoupling.

- Thermal Analysis: Model heat dissipation in dense areas.

Best Practices

- Always keep ground reference planes intact—avoid splitting them unnecessarily.

- Place decoupling capacitors as close as possible to IC power pins.

- Follow shortest return path principle to reduce noise.

- Document your stack-up and routing strategy for future revisions and debugging.

Conclusion

Designing a multilayer PCB layout is both an art and a science. With proper planning, thoughtful stack-up design, and careful routing, multilayer boards provide unmatched performance and reliability in compact electronic systems. Whether you’re developing high-speed communication devices, medical equipment, or consumer electronics, mastering multilayer PCB design is an essential skill for today’s electronics engineers.