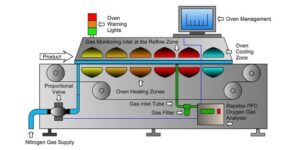

Reflow soldering is an automated process used mainly for surface-mount technology (SMT). Solder paste is applied to the PCB, components are placed, and the board passes through a reflow oven where heat melts the solder. This method delivers high consistency, repeatability, and efficiency—ideal for medium to high-volume production and fine-pitch components.

Hand soldering is a manual process performed with a soldering iron. It’s best suited for prototypes, low-volume builds, rework, and repairs. Hand soldering offers flexibility and precision for through-hole parts or touch-ups but is slower and more dependent on operator skill.

In short:

- Reflow soldering = speed, consistency, and scalability

- Hand soldering = flexibility, customization, and rework

At XPtronics Inc., both methods are used strategically to ensure the best quality and reliability for each project.