In the world of modern electronics, Ball Grid Array (BGA) components play a critical role in enabling compact, high-performance printed circuit boards (PCBs). These components are commonly found in devices such as smartphones, laptops, gaming consoles, and other high-density electronic products. BGAs are prized for their ability to offer superior electrical performance and thermal management, but they also bring unique challenges to the PCB assembly process.

What is a BGA?

A Ball Grid Array (BGA) is a type of surface-mount packaging used to mount integrated circuits (ICs) to PCBs. Unlike traditional packages that use leads (pins) around the perimeter, BGAs use a grid of solder balls on the underside of the component. These solder balls are arranged in a matrix pattern and serve as the connection points to the PCB.

This layout allows for more interconnections in a smaller footprint, making BGAs ideal for applications where space is limited but functionality is high.

Advantages of Using BGAs

- Increased Connectivity: BGAs offer a high density of I/O connections without increasing the package size. This allows engineers to integrate more functionality into smaller boards.

- Improved Thermal Performance: Due to the larger area of contact and efficient heat dissipation through the solder balls, BGAs handle heat better than traditional packages.

- Superior Electrical Characteristics: The shorter connection paths of BGAs result in lower inductance and resistance, which translates to faster signal transmission and reduced electrical noise.

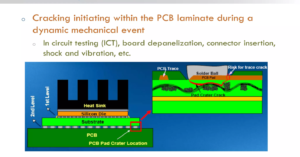

- Mechanical Reliability: The spherical shape of the solder balls helps distribute mechanical stress more evenly, improving the overall durability of the solder joints.

The BGA Assembly Process

Integrating BGAs into a PCB requires precision and advanced assembly techniques. The general process includes the following steps:

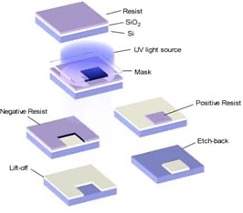

- Solder Paste Application: A stencil printer applies solder paste to the PCB pads where the BGA will be placed.

- Component Placement: Pick-and-place machines position the BGA on the PCB, aligning the solder balls with the paste-covered pads.

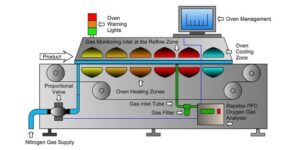

- Reflow Soldering: The board passes through a reflow oven, where the heat melts the solder paste and forms solid electrical and mechanical connections between the BGA and the PCB.

- Inspection: Because BGA solder joints are hidden beneath the component, traditional optical inspection isn’t sufficient. Instead, X-ray inspection is used to verify solder joint integrity and detect defects like voids, cold solder joints, or bridging.

Challenges of BGAs

Despite their advantages, BGAs also present several assembly challenges:

- Inspection Complexity: Since the solder joints are not visible, specialized equipment like X-ray machines is required.

- Rework Difficulty: Removing and replacing BGAs can be complicated and requires skilled technicians and rework stations.

- Thermal Profiles: Precise thermal profiles are critical during reflow to avoid damaging the component or creating weak solder joints.

Conclusion

BGAs have become indispensable in the modern PCB assembly process, offering unmatched density and performance. However, their integration requires advanced assembly practices and careful inspection protocols. As electronics continue to shrink in size while growing in capability, the importance of mastering BGA technology will only increase for manufacturers and design engineers alike.