In the world of electronics manufacturing, precision is everything. Whether you’re building a simple sensor module or a complex multi-layered circuit board, the process begins with a digital blueprint. This blueprint is what we call a Gerber file—an industry-standard format that communicates the design intent of a printed circuit board (PCB) to the fabrication house.

Understanding the Basics

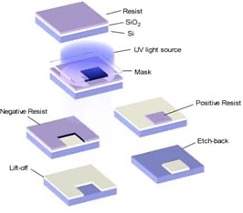

A Gerber file is a type of vector file that describes the various layers of a PCB design layout. These layers can include copper traces, solder mask, silkscreen, drill holes, and board outlines. Rather than containing design schematics or component functions, Gerber files focus purely on physical layout information that guides the fabrication machines during production.

Think of it as the “language” that speaks directly to the PCB manufacturing equipment. It tells the machines where to place copper traces, where to avoid solder, where holes need to be drilled, and how the finished board should be shaped.

A Layered Approach

Typically, each Gerber file in a PCB design corresponds to a specific layer or process:

- Top Copper (.gtl) – Defines the routing of copper traces on the top layer.

- Bottom Copper (.gbl) – Shows routing for the bottom layer.

- Solder Mask (.gts / .gbs) – Indicates areas where solder mask should or should not be applied.

- Silkscreen (.gto / .gbo) – Provides text and graphics like component labels and logos.

- Drill File (.drl) – Details hole sizes and locations for vias and component leads.

- Board Outline (.gbr or .gm1) – Specifies the final shape and edge of the board.

These files are typically generated using PCB design software such as Altium Designer, EAGLE, KiCad, or EasyEDA. Once complete, the Gerber file set is sent to a PCB manufacturer who uses them to fabricate the board exactly as designed.

Why Are Gerber Files Important?

Gerber files are critical to the PCB fabrication process. Without them, a manufacturer would have no accurate way to produce the physical board. They ensure consistency, quality, and exact replication of designs—making them essential for both prototyping and large-scale production.

Moreover, since Gerber is an open and widely adopted standard (originally developed by Gerber Systems Corporation), most PCB manufacturers and software platforms support it. The latest version, called Gerber X2, includes additional metadata to improve clarity and reduce errors.

Conclusion

Whether you’re an electronics hobbyist or a professional engineer, understanding what a Gerber file is—and how it functions—is fundamental when transitioning from PCB design to physical production. It’s not just a file; it’s the bridge between your digital design and the real-world hardware.

By mastering how to generate and review Gerber files, you take full control of your PCB project and ensure that what you design is what gets built.